The IMC Group is the second largest global company for metalworking products. Comprised of over 130 companies in more than 60 countries, they supply a dynamic comprehensive line of precision carbide metalworking tools. IMC member companies produce a wide range of carbide inserts, carbide endmills and cutting tools covering most metal cutting applications, in addition to providing engineering and manufacturing solutions to major industries throughout the world. These companies strive to achieve an environmental impact and responsibility with a compliance program that conforms and commits to improved surroundings.

Treating the environment with great care has been a long and intricate practice in the group and its many companies around the globe. The IMC Group closely monitors its environmental impact by lessening risk factors by addressing products life cycles, starting from raw material to production, transportation, application, packaging and end-of-life management. The IMC Group continuously improves environmental performance values to assure a consistent and responsible approach to its environment.

The IMC Group adheres to the International Standards ISO 14001, which specifies the requirements for an environmental management system to enhance eco-friendly performance. The company commits to this standard in all production units to maintain clean production processes.

Environment, health, and safety policy are set to protect employee’ health and safety while supporting environmental concerns alongside promoting renewable energy, recycling, and waste reduction.

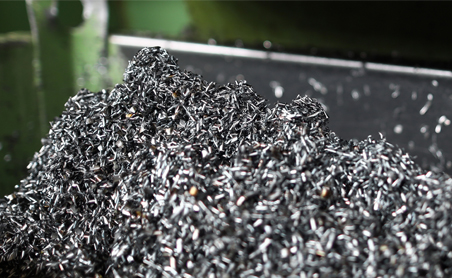

Tungsten and cobalt are strategic metals used to manufacture inserts. Cemented tungsten carbides become available for recycling when scrapped. The IMC Group companies regularly collect scrap metals and carbide from their customers to ensure these sustainable metals are recycled in plants or sold to buyers. The easiest approach for direct reuse is to grind used tools to resurface or rebuild worn tools. Collecting scrap carbide and grinding worn carbide tools assures a cleaner environment.

Waste disposal is treated with high priority where the collection, recycling, and deposition of waste materials is handled daily to assure it is properly treated. The waste management program includes monitoring and controlling the methods by using a highly advanced dedicated computer system in the company’s central control room.

The IMC Group practices methods of sustainable manufacturing by creating advanced cutting tools and inserts through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. The IMC Group’s companies are certified with both ISO 45001, which conforms to safety regulations, and ISO 50001 conforming to energy related issues.

The MATRIX family of automated tool dispensers powered by The IMC Group’s unique management software targets assist to drive down costs, guarantee production output, optimize stock levels, streamline purchasing, control cost per unit and select the right tools for the job to assure sustainable manufacturing.

Sustainable manufacturing is cost-effective. By improving the efficiency of equipment and processes, the company has lowered energy consumption, decreased manufacturing time, reduced waste, and makes use of less material, all of which provide significant cost savings for The IMC Group and its customers